Flush Cooktop

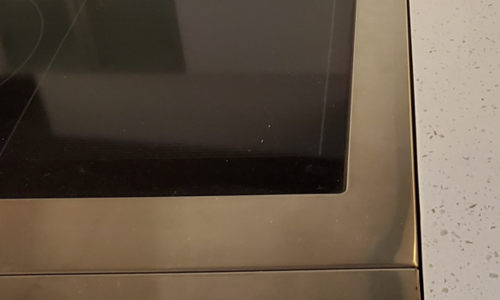

Flush cooktop cutouts - These look great in the showroom but in real life, not so good. There is a gap around the perimeter of the cooktop. No matter how precise the cutout, there will always be a gap. This gap is filled with silicone but inevitably becomes dirty, stained and just gross. Also, many cooktops have 90 degree corners. A cutout with 90 degree corners is susceptible to cracking. | What Not To Do

DCD fabrication Inc. is know for their willingness to take on the most difficult and creative designs. This has given our showroom and contractor partners the freedom to let their imagination run wild. It has also taught us what not to do. Splash with 90 Degree Corners

One piece back splashes with 90 degree corners - Since cabinets have 90 degree corners, back splashes have corresponding 90 degree corners. As a result, there must me a seam at all such corners. Here is a photo as an example. | Flush Sink Cut Outs

Flush sink cutout with square corners - We will provide a flush sink cutout for standard stainless steel sinks with radius corners, We do not offer flush sink cutouts for under mount sinks that have 90 degree corners.

|

L Shaped Countertops

L shaped countertops with mitered edges - Mitered edges have become very popular. A mitered edge has a number of positives but the down side is the corners. An L or U shaped countertop must have a seam in all 90 degree corners. If not, a crack may develop in the corner. However, we have developed a technique to create a stronger corner with a mitered edge. If an L shaped with no seam is insisted upon, we can use this technique to lessen the likelihood of a crack developing but, should a crack occur, it would not be a warranty issue. For an L shaped countertop, it is best to use a laminated square edge with a radius corner. | Drain Boards

Drain board routed into the material. This is another example of looks good in the showroom but doesn’t work well in real life. The grooves are not as well polished so they more easily collect dirt and stains. The water doesn’t really drain into the sink. Our experience is that homeowners regret the feature after living with it. Also, cutting drainboard groves into quartz also voids any warranty. We were even told once "you should have known I wouldn't like it, you are the professional". | Textured Surfaces

Laminated edge with suede, honed or textured finishes. When using a textured material, it is best to employ a mitered edge. The front edge is the same finish as the surface. If you specify a Bullnose or Pencil edge, the textured finish is removed during the shaping process. Then the texture must be recreated on the finished edge. If you look closely enough, you will see a difference in the finish between the factory finish on the surface and the recreated finish on the edge. | Tile

Installing tile before the countertops. Tile should be installed after the countertops. The temptation to tile before the countertops is understandable. If you must, leave the the last couple of rows for after the countertops are installed. |