The Fabrication Process |

Wet Shop

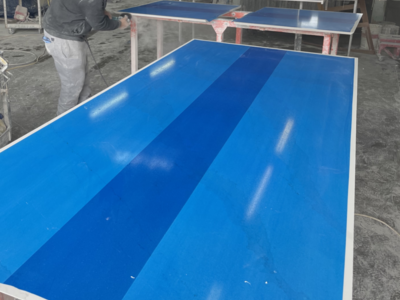

DCD Fabrication Inc. is a wet shop meaning that water is applied to every aspect of the cutting and polishing process. This minimizes dust for a safer cleaner environment for our employees. This is our newest bridge saw, the edge polisher and in the background our water recycling system. | Protecting the Material

Many slabs are delivered with a plastic protective film which is removed for inspection before cutting. After the slabs are cut on the bridge saw, the pieces are recovered with plastic while they make their way through the fabrication process. | Cutting the Slabs

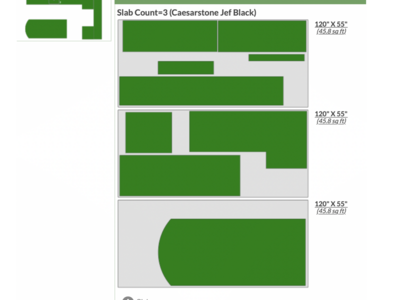

The countertops and edges are cut from the slabs utilizing the Detail Sheet and template. A cut sheet is used to assist the shop in how best to utilize the slabs. In this example, to better avoid potential shading issues, the countertops are all cut from one slab, the island from another and all the splashes from the third slab. |

Edges

The edge material is attached to the countertop using custom mixed epoxy. The edge is then shaped and polished accordingly. |

Cutting the Sink Hole

The sink hole is cut out and polished. The protective plastic is removed and one last inspection is done before loading the finished countertops into the staging area. | One Last Check

The final fabrication step is to clean and double check the countertops. We are looking for and correcting any craftmanship shortcomings. The countertops are then staged and ready for the the installers. |